Auto Degradable Bagasse Cup Making Machine can translate the Plant’s Fiber (Tissue Pulp, Sugarcane Pulp, Bamboo Pulp, Wheat Straw Pulp or Wood Pulp) into the Various Beverage Cups, Coffee Cups and more. The packages are suit for Microwave Oven, Oven, Freezer and Distillation. Moreover, the Package can be used in the fields of International Market as well as Domestic Market.

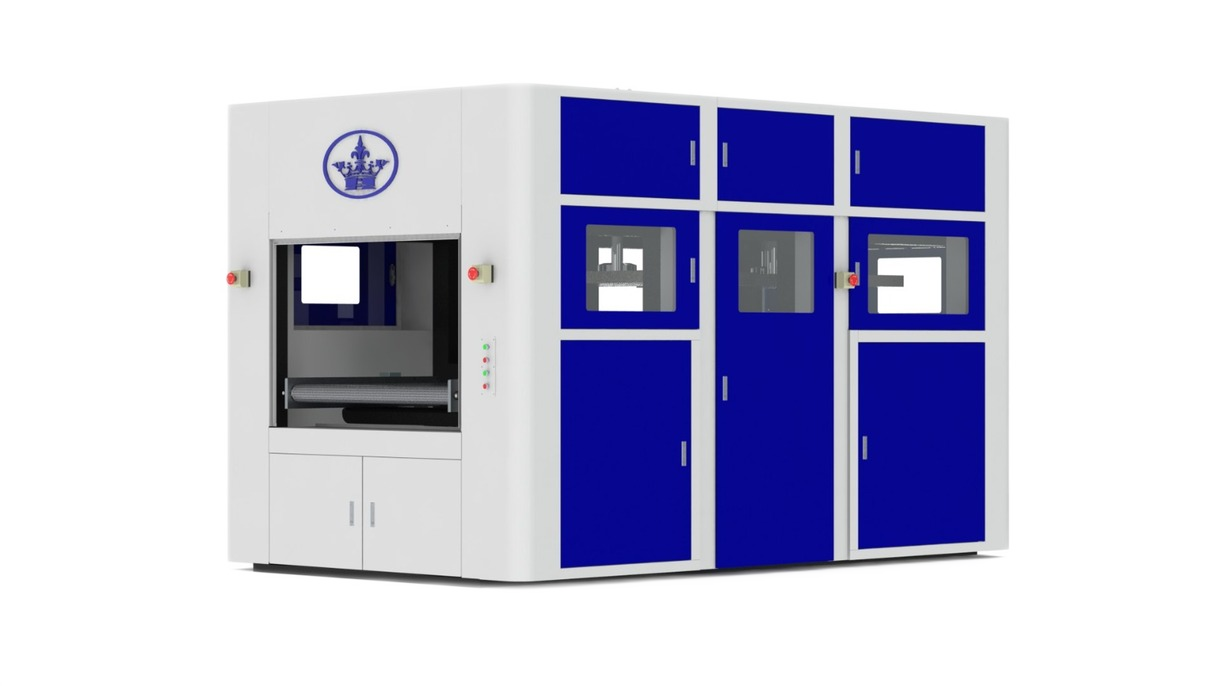

Fully Auto Pulp Molding High-Speed Rotary Forming Machine Line BPMRT-8012

Available Capacity 2 TPD to 100 TPD

Fully Auto Pulp Molding High-Speed Rotary Forming Machine

Advantage - Fully Automatic Pulp Molding Machine

BPMRT – 8012 FULLY AUTO PULP MOLDING HIGH-SPEED ROTARY FORMING MACHINE is designed for Unit Molding and Shaping. Additionally, there is an Environment-Friendly Hydraulic Device along with the PLC System. Our PLC system is built with the modern technology to control each process system which can be Monitored and Adjusted with the Touchable Video screen.

Pulper with Agitator

SS Pulp Tank

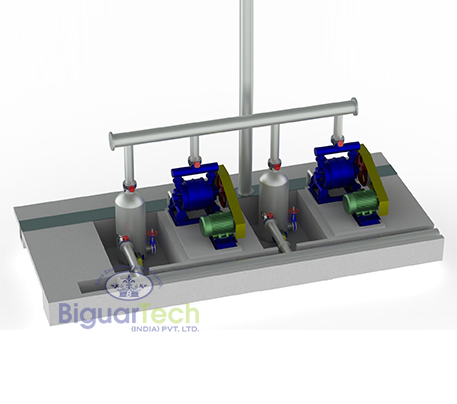

Pumps

Flow Control System (FIC / CRC)

Chemical Tank with Pump

Double Disk Refiner

Main Forming Machine with Stacker

Vacuum with Separator Tank

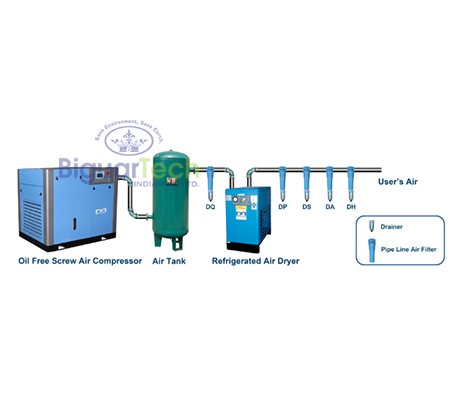

Air Compressor with Dryer

Pulp Filter System

Cooling Tower

Operating Control System

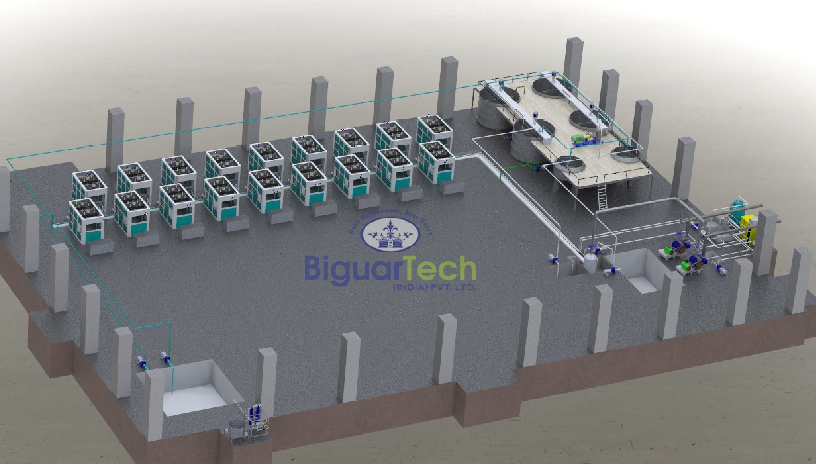

Plan Layout

Application

The machine can translate plants fiber sugarcane pulp, bamboo pulp and wood pulp into food packages such as western-style food, dish, bowl, box, supermarket vegetable tray and various beverage cup, coffee cup and more. The packages are suit for microwave oven, oven, frozen, and distillation.Besides, Industrial packaging, electronic Packaging, Games packaging, and Cosmetic packaging can be manufactured. The packages are suited for the environment and are 100% biodegradable, 100% compostable, Durable insulating, and impervious to high temperatures. It’s stronger and more durable than Styrofoam and other types of packaging.

Features

You must be thinking “Why would You purchase our Machinery / Why would You do a business with us?” So, here are some of the points;

- We are having Modern Technology which is far more better, probably the best than others. We just do not believe in Expertise,Our Engineers are experts as they are having 15 years of experience in the machinery line…

- We produce the Lowest Weighted Products from Our Machinery and the Lowest Thicknesse. 0.4 MM only.

- We use Thermocouple System, an Optical Fiber which is an Advanced Technology of the Sensor.

- We have imparted the FIC & CRC System which can control Additional Raw-Materials like Water, Pulp and Chemicals.

- We use Buckle System. There is No Screw or Bolt as there is no chance of Blocking of the Pulp. If it does, variation comes in the Final Product.

- Amazingly, we have Auto-Trimming & Auto-Stacking System and for that, no other extra machine is required.

- You will get 100% Production from the 100% Raw-Material’s use that simply directs you to 30% Energy Saving.

- You would need only 140 °C Temperature for Heat Pressing.

Technical Parameters

| Item | Specification |

|---|---|

| Machine Model | BPMRT-8012 |

| Mold Size | 800 x 1200mm |

| Production Capacity | Upto 100-500 Kg/24Hrs |

| Cycle Time | 40-50 Seconds (Depends upon products specification) |

| Weight | Approx. 6 Tons (Excluding Mold) |

| Dimension | L 3614mm/W 2170mm/H 2500mm |

| Machine Body | Ductile Iron |

| Heating | Electric Heating |

| Electric Heating | Multifunctional – Tableware & Industrial Packaging. |

| Control Type | P.L.C |

| Noise | ≤ 85dB |

| Packing | Complete Machine, Crate |

Due to technological innovation, the technical specification can be changed.